Cost Saving Workflow

Cost Saving Workflow

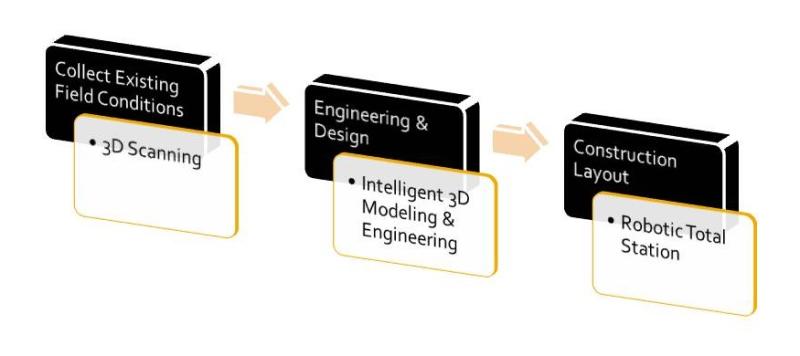

In order to deliver a cost effective schedule driven project, we use a “Cost Saving Workflow”. Our objective is to reduce cost and schedule overruns by providing the construction craft the most accurate information in a timely manner.

We accomplish this in a three phase process using the latest technology tools for the construction industry. These are 3D Spatial Imaging (3D Scanning), Intelligent 3D Modeling, and Construction Layout using the Robotic Total Station. Below each phase is outlined in more detail.

For examples of this process, select the slide show to the right "Technology at Work"

Phase I: 3D Scanning

Click here for examples of 3D Scanning

In order to get accurate as-built information from the existing building, we utilize 3D scanning technology that collects millions of data points called a “Point Cloud” in hours not days. The information collected by scanning in one day would historically take multiple people weeks to measure. This data will then be used in conjunction with the new 3D engineering/design phase of the project. The “Point Cloud” will be tied into the project control datum.

Phase II: Intelligent 3D Engineering/Design Modeling

Click here for examples of Design and Engineering

In order to accurately tie into existing building systems, we utilize the scanned data to locate existing mechanical systems. The new mechanical systems will then be routed through the existing area to detect any potential clashes. The new model will also be tied into the project control datum.

All new mechanical systems will then be intelligently modeled and coordinated with other project disciplines. The deliverables from this model will be plan and section drawings, equipment and pad layouts, fabrication quality piping isometrics, and bills of materials.

Phase III: Construction Layout with Robotic Total Station

Once the project has been coordinated and approved, the 3D model will be exported out to the robotic total station collector. Then items such as pumps, pipe hangers, floor/roof penetrations etc. can be quickly and most importantly accurately laid out. Our experience is that the same amount of layout work can be accomplished by one person in a single day with the Robotic Total Station compared to five days with two people.

Advantages of Construction Layout with the Robotic Total Station:

· Construction layout with the robot can be completed about in about one tenth (1/10) of the time compared to conventional layout methods.

· Layout can be done prior to the release of Issued for Construction documents.

· Eliminates common craft layout errors using strings, plumb bobs etc.

· Ensures pre-fabricated piping, duct, etc. will fit in its intended location.

We Invest in Technology to Save You Money

At PLC, we pride ourselves on applying the very best technological solutions to perform our work accurately and on schedule.

Services We Offer

- Mechanical and Structural Engineering, Civil Engineering

- Piping Design and Engineering

- P&ID Support (creation or revision)

- Pipe Stress and Structural Steel Analysis

- MEP Coordination (BIM Modeling)

- Isometric drawings

- Material take-offs

- Cost estimating

- Issue for Construction packages

- 3D Spatial Scanning

- Robotic Total Station Construction Layout

- PE Stamped drawings